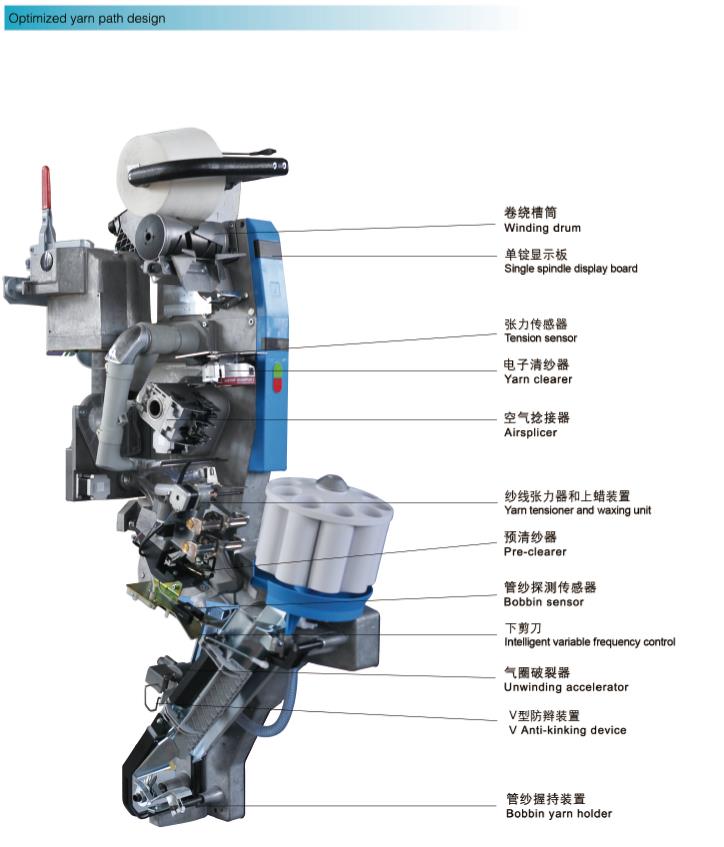

WINDER / ROVING / ROTOR / RING

FARO Automatic Winder

Innovative new yarn parth Design

Excellent Building Of Yarn Package

Intelligent Joint Cycle

Stable Winding Tension

Total Control ot Yamn Qualty

Reduction of Power Consumption

Product Seriation

Convenient Maintenance

First Class After Sale Service

Innovative New Yarn Path Design

Perfect Combination of Mechanical anti ribboning and Electronic anti ribboning

Innovative New Slotted Drum Drive

Intelligent Joint Cycle

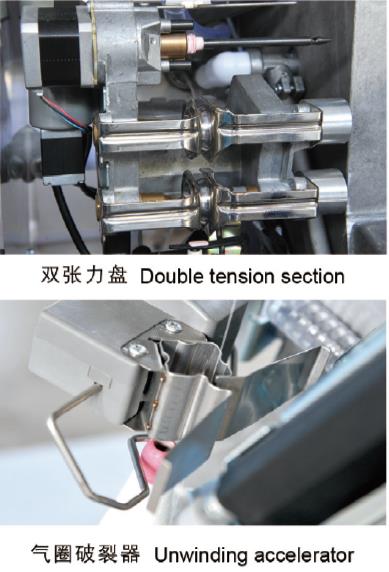

Double Tension Section Tension Control

Innovative New anti ribboning Motor, Air Door Mechanism Design

Tension Sensors Ensure Constant Tension Winding

Product Seriation Design

Convenient Maintenance

First Class After. Sale Service

FARO Automatic Winder

Classics of perfect and modern technology

12-72spindles 2200m/min Reduction of Power Consumption

FARO Automatic Winder

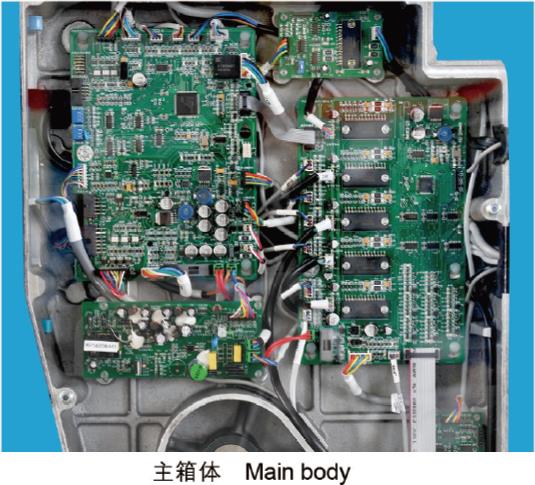

FARO - the lighthouse in the sea voyage, the leader ofdomestic winder technology.FARO automatic winder isthe fourth generation of automatic winder launched by Sino Machine Group,CHTC QTM. followed by GA001,ESPERO, ISPERO, which inherits the perfect windingtechnology and extensive material adaptability; Thecombination of new yarn path design and advancedelectronic control technology realizes the intellectualcontrolled splicing cycle; Modular design, simple structure,lower energy consumption; lt realizes complete yarnmonitoring, and ensures higher efficiency, better yarnquality and outstanding economic efficiency.

Higher efficiency

Optimized yarn path design; Stable winding tension;Efficient joint cycle.

Superior yarn package and yarn quality

Unique anti ribboning way combining mechanicalanti anti ribboning with Electronic anti ribboning;USTER QUANTUM3 and LOEPFE ZENIT+ electronicyarn clearer; Tension sensors ensure constanttension winding; stable unwinding tension due tounwinding accelerator matching with V-shaped anti-braid bar; MESDAN splicer; Import slotted drum.

Reduction of power consumption

Main suction motor controlled by inverter, motordirect-drive; Slotted drum directly driven by DCbrushless motor; Joint cycle controlled by sensorand independent motor.

HMI dialogue

Direct and clear display of single's LED alarm; Multi-lingual touch screen; Convenient data setting and production data statistics.

Product line complete

FARO-M yarn library automatic winder, FARO-Rrewinding machine, FARO-L winder with doffingtrolley, FARO- E tray type automatic winder, FARO- F fine complex type automatic winder, automatictube arranging machine can be equipped according to user requirements.

Frst class after-sale service

Professional after-sale service team, fast sparts supply.

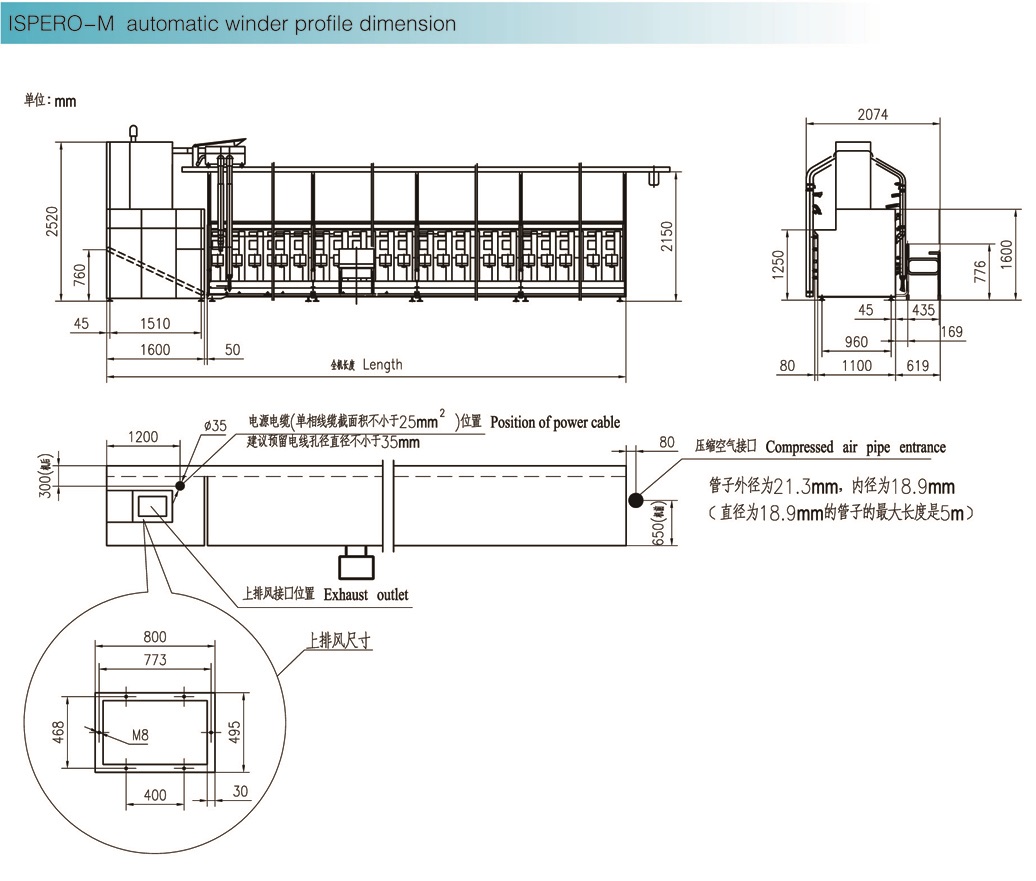

Optimized yarn path design

Best Design of Anti-patterning and with excellent Quality of yarn package

Innovative Best Design of mechanical anti patterning. combining with electronic anti patterning. can effectively avoids Patterning

The clearer controls real-time winding process Ifrom the movement it activated, if thread ¡s Ibroken or yarn fault occurs, the clearer producesthe immediate lifting of the package from windingdrum and package finish braking. The absence offriction between package and drum prevents yarn worn.

Uniform and constant package density

Package cradle is pneumatically pressurized to eliminate drum vibration. The uniformity of package density on all winding head is guaranteed by centralized setting.

Stable Winding Tension

Uniform yarn tension

Double section yarn tensioner electromagnet pressurized with centralized pneumatic setting guarantees a uniform winding tension, since tensionis divided into two points. The centralized settingon headstock for tension section according to yarntype can meet the requirement of lot change onone machine. Tension close loop control systemguarantees package shaping and uniform density. Itoffers lighter pressure to the yarn, and reduces the

Wear and tear for yarn; The tension sensor ensuresthe stability of winding tension, and improves thequality of package forming; The V-shaped anti-braidbar matching with unwinding accelerator effectivelyreduces the unwinding tension fluctuation, andguarantees the evenness of yarn unwinding tension;

Inelligent joint cycle and winding monitoring

The inspector control system controls each action of joint cycle and headstock sets

parameter so that it can obviously shorten splicing time, enhance production efficiency,

reduce unnecessary action, compressed air consumption and lints.

When yarn winding on drum or belt yarn etc abnormal condition is found, photocell anti-patterning sensor immediate alarms and stops so as to enhance efficiency and guarantee package shape and precis epackage length.

The LED display of each spindle can show two Chinese words or one English word and show both state and spindle alarm messagefor treatment by maintenance worker.

The slotted drum adopts brushless motor coaxial drive

The slotted drum adopts brushlessmotor coaxial drive, which improves thetransmission efficiency, raises the maximum speed of revolution, so as to im proveproduction efficiency;

Compared with the traditional synchronousbelt transmission, due to eliminating the power loss caused by belt friction, it reduces the power consumption and noise.

Main suction motor controlled by inverter, motor direct-drive

The main suction motor is controlled by inverter, to make the suction negative pressure constant;

When there is less air consumption, through the information transfer by pressure sensor, the motor runs at a lowspeed, which not only reduces the energy consumption, but also reduces the noise. Fan impeller adopts motor coaxialtransmission, to avoid the power loss due to belt transmission friction and sliding, with the effect of saving energy andreducing consumption, and reducing the noise at the same time.

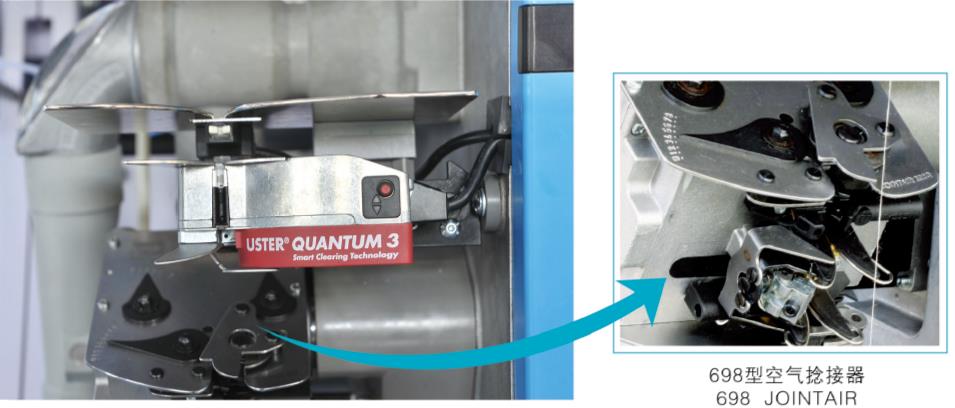

Top level electronic yarn clearer, total control of yarn quality

Yarn clearer controls yarn quality during all winding process including joint quality. Two different kinds of yarn clearer settings are adopted for normal winding and joint.

Great flexibility of splicers, guarantee of fine joint quality

Strategic cooperation with the leading splicer manufacturers in the worId guarantees fine joint quality and meets the trend of textile industry.

698 Jointair

Different chambers and covers can be adapted to suit the splicing of cotton, wool, manmade fiber and their blends.

4923 Aqua-splicer

Aqua-splicer is mainly suitable for the splicing of slub yarn, core spun yarn and compact ring spun yarn etc various kind of fiber.

4983 Heat splicer

Heat splicer is applicable for the splicing of pure wool or wool -polyester yarn.

Covenient inspector control system can save the prodction detaied information fo 30 days

The inspector control system coordinates the automatisms, gather data and provide an interface

with the operator.

Gradual acce leration of winding drum with preset sequence for optimum yarn deposit on thepackage and precise yarn length .

Continuous dialogue with e lectronic clearerfor exact reading of yarn fault dimension, consumption and classification of yarn fault .

Auto diagnosis with immediate identification of the cause of the fault for minimizing spindle down -time .

The inspector Control System centralized control yarn tension and ensure good package shape .

The inspector Control System and I pneumatic panel jointly control each twisting par ameter andefficiently control joint quality .

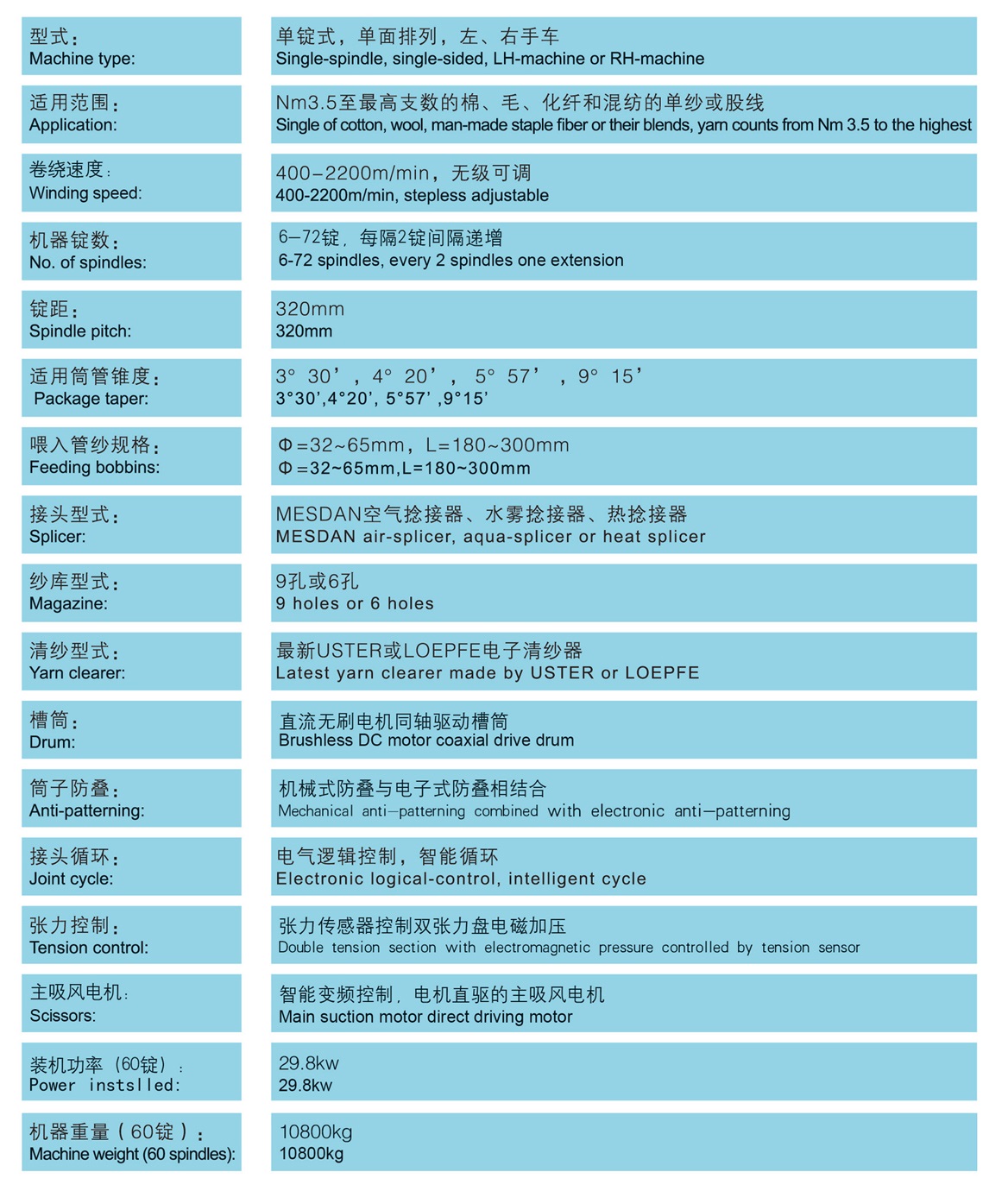

FARO automatic winder profile dimension