WINDER / ROVING / ROTOR / RING

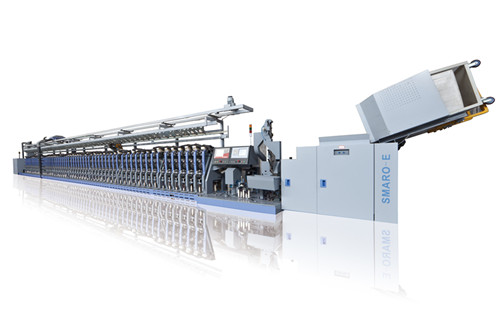

SAMRO-E AUTO-WINDER WITH TRAY

SMARO-E automatic winder with tray is a new generation winder, self-developed by CHTC. It inherits the advantages of SMARO automatic winder and SMARO-I automatic winder linked with spinning frame, adopted optimized designed tube yarn treatment and single spindle tube change mechanism, increases big magazine, realizes flexible connection with spinning frame, adopts advanced control technology, realizes self-diagnosis, self-supply and yarn monitoring during whole process, greatly enhances its automation and intellectualization degree.

Flexible bobbin treatment system

NEW GENERATION AUTO-WINDER

INTELLIGENTIZED MAGAZINE SUPPLY TUBE YARN

Intelligentized supply tube yarn of magazine

High quality and high efficient piecing unit

Flexible bobbin treatment system

High efficient and intelligentized doffing carriage

Feeding yarn by big magazine can great reduce labor

Need not manually insert tube, operator only need to push tube box from spinning frame to winder for winding. The whole process realizes automatic and successional production and enhance production efficiency. Compared with common auto-winder, it can reduces 70% labor.

On-line detection, self-diagnosis and self-supply

According to actual production, on-line detection and feedback from sensor automatically start virbration transportation and tube yarn feed , featured by maximum automation and flexiblility.

The Inspector Control System Realizes Complete, Control over running accurately

4-grade menu dispalys HMI, sensor collects data, Headstock lively displays actual fault position, lively reports tube yarn treatment, which can meet the requirement from high grade user.

HIGH QUALITY AND HIGH EFFICIENT PIECING UNIT

★Light-fiber sensor detectes piecing action exactly.

★Upper/lower air door control to enhance piecing success rate and efficiently reduce air comsuption.

★Vertical suction moves up and down along straight rail to enhance motion precision.

★ Suction nip and vortex blowing system resonably fit with tube diameter greatly increase piecing rate.

★Two set of piecing unit meet long distance tube yarn supply in maximum.

INTELLIGENTIZED MAGAZINE SUPPLY TUBE YARN

★Bobbin yarn is supplied by bucket instead of manual supply and each spindle is provided with spare bobbin transporting channel.

★Automatically adjust vibration frequency according to bobbin requirement to ensure bobbin supply continuity.

★Intellectually identify big end and small end, accurately and effectively put bobbin onto tray.

FLEXIBLE BOBBIN TREATMENT SYSTEM

★Introduce the latest high grade logistics idea.

★Multi-channel logic judgment ensure every bobbin treatment action, such as draw up of full bobbin, empty bobbin, bobbin reading , bobbin re- reading in order without interference.

★Empty bobbins go back automatically on conveyor loop, so bobbin treatment pressure is alleviated effectively.

★Concentrativelly collect empty bobbins and automatically identify empty bobbin from skinny one.

★Be able to treat various bobbins with different dimension and specification.

HIGH EFFICIENT, INTELLECTUAL NEW TYPE OF DOFFING CARRIAGE

★High efficient automatic doffing and doffing circle;

★Traverse speed 60m/min;

★Doffing package diameter max Ф300mm;

★Intellectualized single spindle automatic re-start;

★Brife automatic piecing action and piecing yarn fixing position is adjustable;

★Smartjudgement of bobbin and package yarn in existence to ensure favoring doffing;

★Manual and automatic is optional for convenient doffing adjustment;

★Automatic package transportation;

CHOICE OF VARIOUS SPLICERS

GUARANTEE OF FINE JOINT QUALITY

Cooperation with the leading splicer manufacturers in the world guarantees fine joint quality and meets the trend of textile industry.Splicing system adopts modular-design for easy installation and maintenance. Different types of splicers can be interchanged according to different customer requirements.

698Q JOINTAIR

Different chambers and covers can be adapted to suit the specific requirements of the material to be spliced, such as cotton, wool, manmade staple fiber and their blends.

4923Q Aquasplicer

Aquasplicer mainly suitable for the splicing of slub yarn, core spun yarn and compact ring spun yarn.

Uniform and consistent yarn tension, excellent building of yarn package

New type of electronic anti-pattering system, adopting balance pressure regulating in ratio, functions during the whole winding process to eliminate the formation of critical patterned yarn. Multi-type of drums optional for different yarns meet the requirement of package building and capacity.

New type of closed drum cover can efficiently prevent package yarn tail from throwing off, greatly reduce yarn wrap on small bobbin side, prevent bobbin building problem, enhance one-time head suction successful rate.Electronic anti-wrap drum can prevent yarn wrap on drum and stepped winding yarn, optimize package building and reduce material waste.

Newly increased tension close-loop control ensures even doffing tension, enhance winding speed 10-20% and production efficiency 2-5%.

Optimized system structure to enhance production efficiency

Comparing with traditional belt drive, DC brushless motor coaxial drive winding drum could reduce the electricity consumption and improve the productivity due to the elimination of the power loss caused by belt friction and slipping

Package yarn head suction program is optimized, which efficiently prevent the problems such as yarn choking on package yarn suction nozzle, enhance production efficiency 1-2% and enhance machine operation reliability.

New type of soft tension structure can stabilize yarn tension and enhance production efficiency.

DRUM DRIVEN BY A COAXIAL

CONNECTED BRUSHLESS DC MOTOR

☆Drum driven by a coaxial connected brushless DC motor, aiming at high driving efficiency, low power consumption and superior package quality

☆Compared with the traditional belt drive, the coaxial drive eliminates the power loss caused by belt friction and sliding. Thereby the productivity is improved due to the lower power consumption.

☆Electronic anti-patterning system functions during the whole winding process to eliminate the formation of critical patterned yarn. The anti-patterning cycle and range is pre-set in HMI and changed automatically according to the dynamic package diameter.

☆Yarn clearer monitors whole winding process. When yarn breaks or defect occurs, package lifts instantaneously for package brake , which ensure no friction between package and drum during instantaneous brake.

☆Drum speed is accelerated gradually which ensure synchronization and free of slippage between package and drum during winding process and ensure precise package yarn length.

TOP LEVEL ELECTRONIC YARN CLEARER,

WHOLE PROCESS CONTROL OF YARN QUALITY

Electronic clearers control yarn quality, including yarn joint quality, during the complete winding process. Two different yarn clearer settings are adopted for normal yarn winding and yarn joint respectively. The most advanced electronic yarn clearer models can be equipped. Foreign fiber detecting function can be chosen as optional.

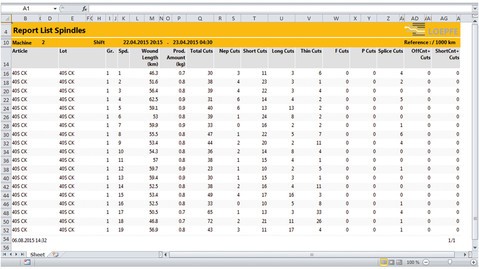

MAIN TECHNICAL SPECIFICATION

Spindles: 6~64

Type : single-spindle, single-sided arrangement, left hand or right hand

Application : cotton, wool, synthetic fiber and blended staple fibre or twisted yarn

Processed yarn count : from Nm3.5 to the highest

Working negative pressure : speed adjusted by inverter

Drum : driven by DC brushless motor

Package hold : front bow style

Package dimension : Length 180~230mm, Diameter 32~43mm

Winding speed : 400~2200m/min,steepless speed adjustment

Splicer : MESDAN airsplicer,Aquasplicer

Electronic clearer : USTER/ LOEPFE

Piecing ability : 40 Bobbins/min

Storage of yarn tube : 2 tubes

Tube delivery speed : 25 meters/minute

Channel number : 2 for tube forward, 2 for tube backward

Power installed : 37.9kW

Overall dimension: 26667 X1818X2650mm(60 spindles)