CARDING COTTON

JWF1235 CARDING MACHINE

JWF1235 type high production carding machine is the latest product developed by CHTC QFT / Sino Machine Group (hereinafter referred to QFT) in 2013. Basing on years' carding machine development and manufac-ture expertise, as well as absorbing the advanced technology of both at home and abroad, QFT launchedthis new generation carding machine. While maintaining the process and technology of many mature cardingmachines, JWF1235 optimizes the mechanical structure by adopting the function module design. It combinesboth practical and aesthetic excellence.

1. Electric control panel1.2. Chute feeder3. Feeding system4. licker. -in parts5. Web cleaner

6. Aluminum alloy big undercasing7. Flat top parts8. Cylinder parts 9. Stationary flats

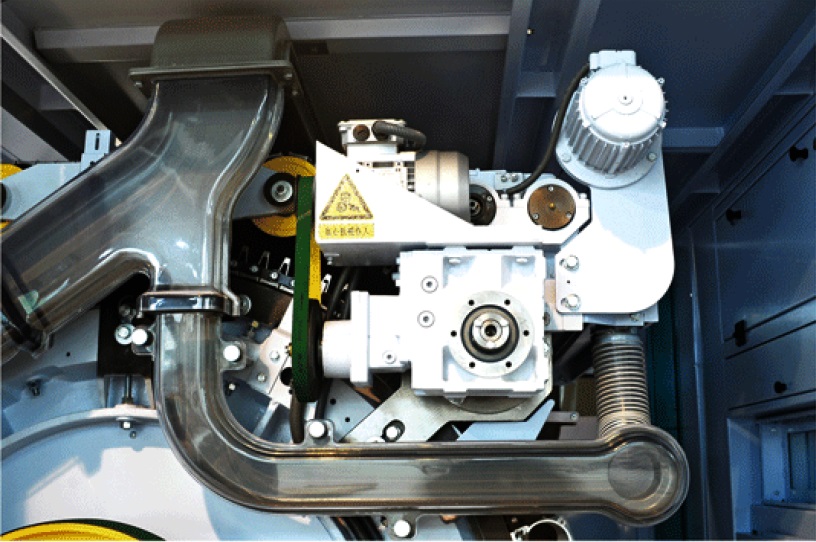

10. Doffer parts 11. Three roller stripping parts12. Web take- - off device13. Front calender parts

Consequent cotton feeding. The feeding direction of feed roller is the same as the entry point motion directionof licker-in (at the entry point, both feed roller and licker-in move upward). At the entry point, the fiber damageis largely reduced, and the short fiber is less.

Equipped with more aluminum alloy front and rear stationary fats, the carding area is enlarged.While increasingproduction, it can make sliver cleaner and fiber more even. The density of the stationary fats increases gradually.The excellent tip fatness and convenient gauge adjustment ensures the complete and fine carding of the fiber.Web cleaner, stationary flat and cover sheet are of modular design, which can be configurated according to thevarious materials. This design is also character-ized with its flexible disassembling and better efficiency inimpurity removing.

The reversed revolving flats improve processing technology and reduce workload, which can help to reduce thecost and save energy with lightened weight. Reversed revolving flats increase carding action and improve webquality. Driven by separate converter motor, the active flats' speed is con-venient to adjust online to achieve thebest carding effect.

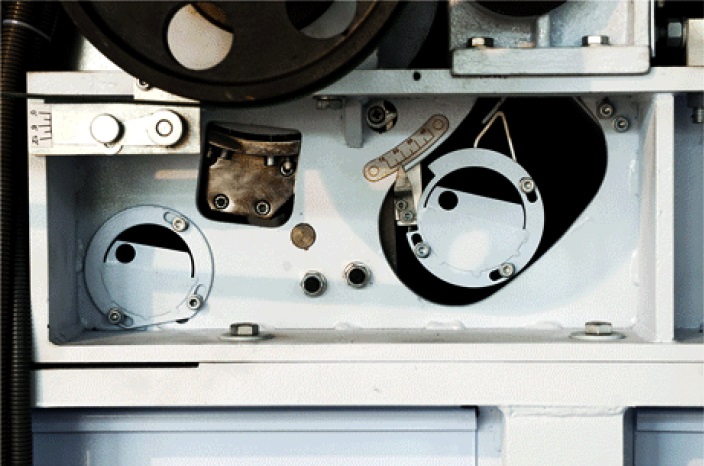

The dust mote knift of licker-in is adjustedaround licker-in's centre. The adjustmentcan be stepless and the machine has notto be stopped.

The visible plastic adhesive filtering pipes arefeatured by their smooth appearance and easymaintenance. The multiple continuous suctionpoints and continuous pressure monitoringguarantee its excellent suction efficiency.

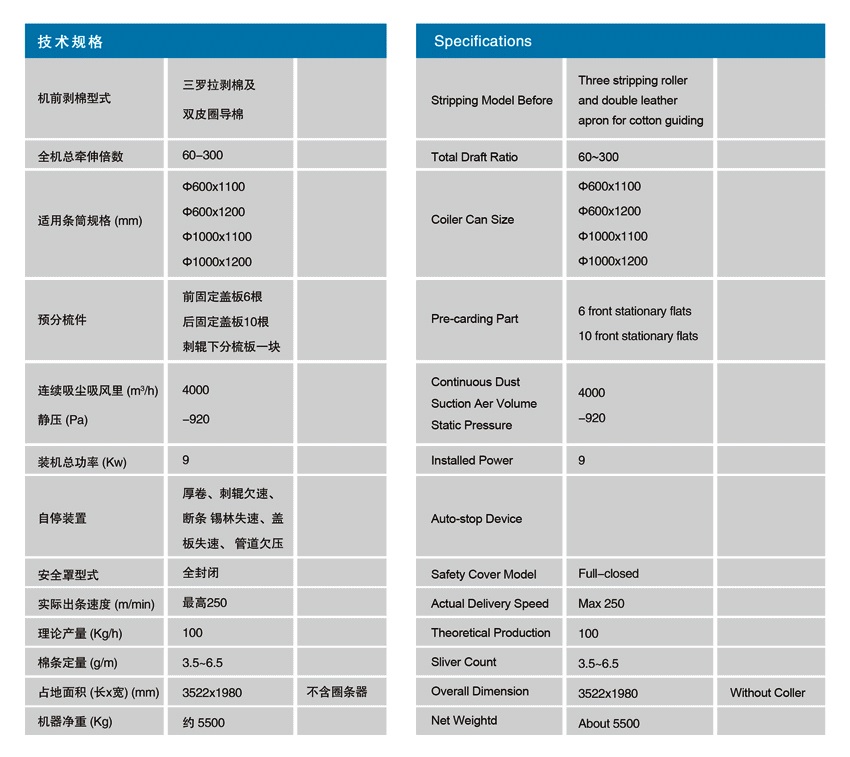

Specifications